Willeby’s plan for blueberry harvester attracts UGA’s attention

Published 5:41 pm Wednesday, December 30, 2020

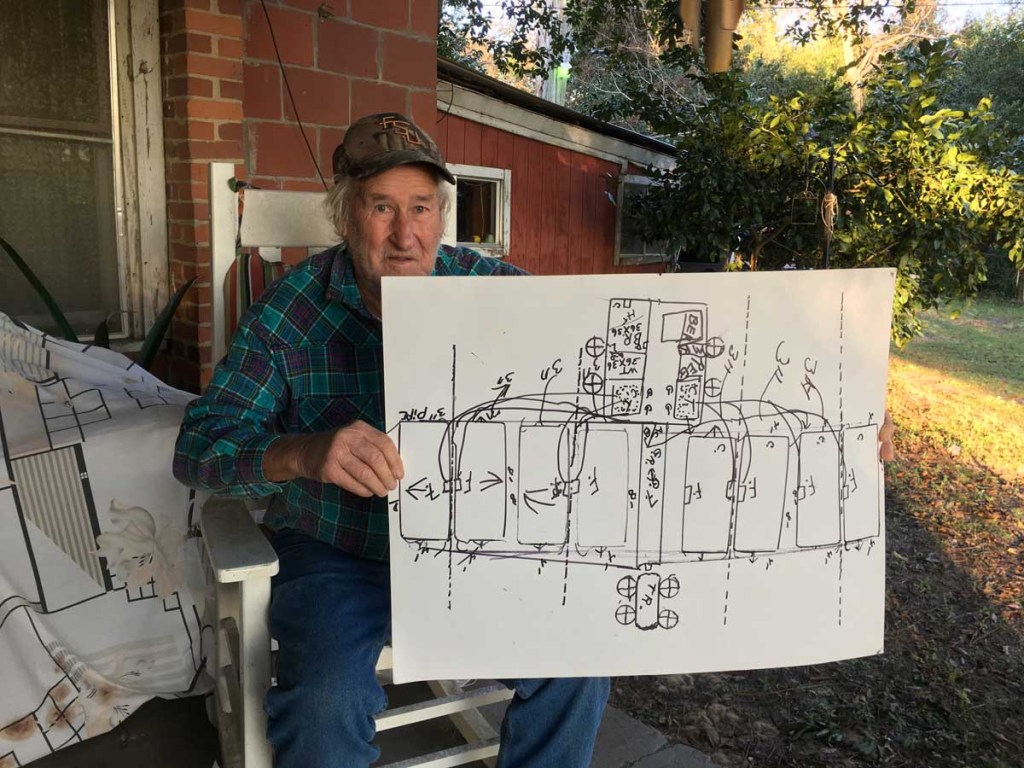

- Billy Willeby of Coolidge holds up a poster on which he's sketched his idea for a blueberry harvester. Extension agents from the University of Georgia visited Willeby's home Dec. 1 and came away impressed with the idea — but they wished he'd had a prototype so they could see the idea in action.

COOLIDGE, Ga. — A Coolidge inventor is getting some support from the University of Georgia and area manufacturers for a design he believes will revolutionize the way blueberries are picked.

Billy Willeby, now 82, holds the patent for the Boll Saver, an attachment that uses pressurized air to harvest more cotton from a bush, leaving less on the ground after the harvester passes over. He’s come up with a number of other devices, many of them related to agriculture, that he’s not bothered to patent.

Trending

The blueberry harvester he’s come up with exists only on paper right now, but Willeby said he’s working with area manufacturers to get a prototype made.

Renee Holland and Sydni Barwick of the University of Georgia Extension Service visited Willeby’s home Dec. 1 but were a little disappointed they couldn’t see a prototype. Holland, the area blueberry agent for Bacon County, said she told him she’d keep him in mind as UGA moves forward with grant proposals to work on harvester efficiencies.

“I do feel that he has some brilliant ideas,” Holland said in an email to The Observer. “I would like to see a prototype, though.”

Willeby said the idea to shake blueberries from bushes came to him while he was out in the yard. There was a board on the ground with a nail in it. He didn’t notice right away, but the other end of the board was resting against some blueberry bushes.

“I picked up a four-pound hammer and gave it about three whaps and down came the berries,” he said.

He said the principle is similar to the way nuts are shaken from pecan trees.

Trending

Willeby expanded his device from that simple beginning to a 42-foot-wide implement to be towed behind a tractor. As he explained it, the tractor would creep forward with four rows of blueberry bushes passing between the modules of the harvester. A vibrating beam would shake the bushes, and the berries would fall into a unit designed to cushion them and direct them into an air flow that would carry them to a trailer that follows behind the harvester. In the trailer, graders would sort the berries so that they could be packaged right in the field.

“This unit will do the work of 100 hand pickers,” Willeby predicted. He said it would take only six people to operate it: one to drive the tractor, one handler and four graders in the trailer.

Willeby said the reduction in labor would save farmers money, and it would help in the case of a labor shortage, such as the one now being experienced due to COVID-19. He said he believes the implement could be adapted to harvest other fruits and vegetables too.

He also predicted it would cause less damage to berries: a 1% loss instead of what he described as a 30% loss caused by smaller blueberry harvesters now in use.